|

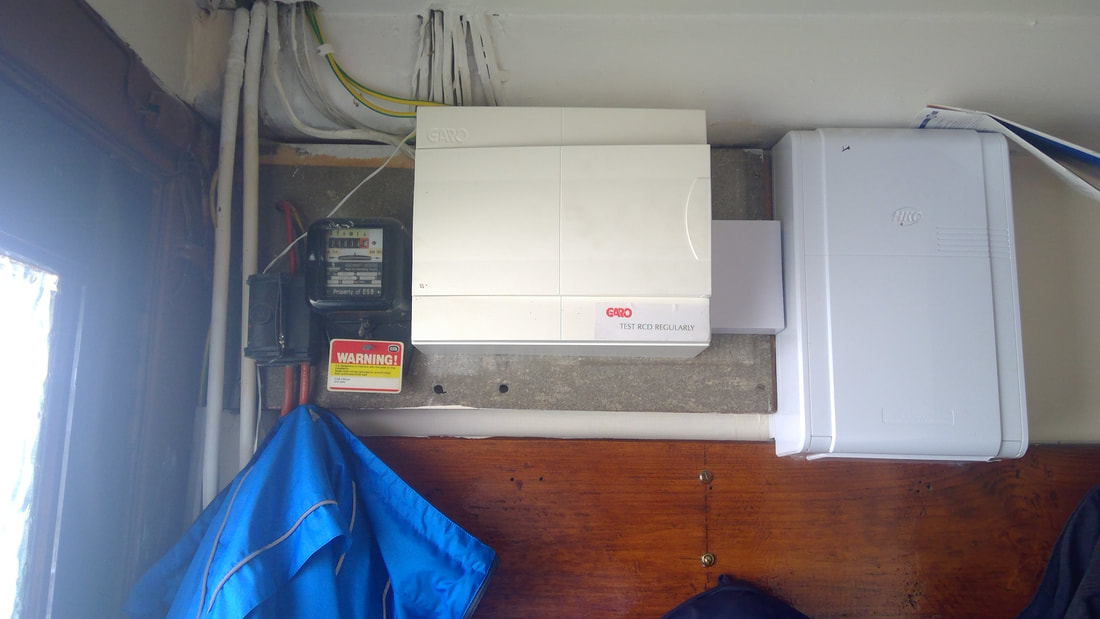

Many homes in Ireland built before 2000 contain Asbestos Containing Materials or ACMs. Some of the more common ACMs in Irish homes are: Textured coatings/stippled ceilings  Textured coatings, also known as stippled ceilings, Artex, popcorn ceiling, decorative coatings were very popular in the 70's and 80's. They usually contain between 3-5% Chrysotile asbestos. Typically, the textured coatings are well encapsulated with years of paint. The risk of fibre release is low but may occur when subject to abrasion. Asbestos Insulating Board Typically found behind old fuseboards or on garage ceilings, Asbestos Insulating Board or AIB usually contains between 16-40% Amosite asbestos. Aas this is a semi-compressed board it is more likely to release fibres as a result of damage or abrasion. Work on AIB can give rise to high levels of asbestos fibre release. Asbestos Cement Products Asbestos Cement Products may include slates, corrugated sheeting, gutters, downpipes, flues and cowls. They generally contain 10-15% asbestos bound in cement. The asbestos fibres are usually firmly bound within the cement matrix but can be released through mechanical damage or deterioration from weathering over many years. How will I know for sure? A survey, carried out by a qualified asbestos surveyor, is the only way to be sure if there are Asbestos Containing Materials in your house. The surveyor will take samples of suspected materials which will later be analysed in a laboratory. They will also carry out a risk assessment on any Asbestos Containing Materials found and give advise on whether they can be managed in situ or should be removed.

If you would like further information on they types of survey that we conduct, or if you have any questions about asbestos please get in contact with us.

1 Comment

There has been a lot of talk around the world lately about the dangers of Silica dust. So much so, the Health & Safety Authority have started to make a lot of noise about it too - and rightly so. I have been speaking to colleagues in the States who have told me that OSHA have really cracked down on the control of Silica dust and they believe that the industry evolving around the control of Silica dust will be bigger than the Asbestos industry. So, what is Silica dust? Silica is one of the most common naturally occurring elements on the planet. Silica, the mineral compound silicon dioxide (SiO2), is found in two forms -- crystalline or noncrystalline (also referred to as amorphous). Sand and quartz are common examples of crystalline silica. Many common construction materials contain silica including, for example, asphalt, brick, cement, concrete, drywall, grout, mortar, stone, sand, and tile. What are the dangers? Inhalation is the primary route of exposure to crystalline silica dust. For any kind of dust, there are different particle sizes. When dust is inhaled, its point of deposition within the respiratory system is very much dependent upon the range of particle sizes present in the dust. It is the respirable (smallest particle size) fraction of crystalline silica dust which is of critical concern for its health effects, since these can penetrate deep into the lung. Inhalation of fine dust containing crystalline silica can cause lung damage (silicosis), which in severe cases can be disabling, or even fatal. Silicosis is irreversible and treatment options are limited. Workers may develop any of three types of silicosis, depending on the concentration of airborne silica: • Chronic silicosis, which usually occurs after ten or more years of exposure to crystalline silica at relatively low concentrations. • Accelerated silicosis, which results from exposure to high concentrations of crystalline silica and develops five to ten years after the initial exposure. • Acute silicosis, which occurs where exposure concentrations are the highest and can cause symptoms to develop within a few weeks to four or five years after the initial exposure. Workers exposed to RCS are at increased risk of developing lung cancer. Similar to Asbestos, Silica dust can be transferred on clothing. The National Institute for Occupational Safety and Health (NIOSH) recommends that workers avoid bringing silica dust home from work by:

How do we protect our workers? • The first step to controlling crystalline silica is to carry out a Risk Assessment. • Seek to substitute the silica containing material with a suitable alternative if possible. • Use safe systems of work such as wet methods for dust removal/suppression. • Engineering controls such as Local Exhaust Ventilation (LEV) or containment measures should be used where appropriate. • Wear suitable PPE such as coveralls and appropriate gloves. • Respiratory Protective Equipment (RPE) should either be a FFP3 disposable respirator or a P3 particulate filter fitted to a half or full face mask to provide effective protection and be CE marked. All RPE should fit the employee correctly. • Any RPE worn should be properly fit tested. What are the legal requirements? The respirable fraction of the dust is invisibly fine and the OELV for Respirable Crystalline Silica (RCS) is 0.1mg/m3 averaged over 8 hours, as set down in the HSA Chemical Agents Code of Practice under the Safety, Health and Welfare at Work (Chemical Agents) Regulations 2001. A risk assessment under these regulations is required where exposures to RCS can occur. The Safety, Health And Welfare At Work (General Application) (Amendment) Regulations 2016 S.I. No. 36 of 2016 contains a Prohibition on silica – Regulation 128 “An employer shall ensure that no sand or other substance containing free silica is introduced as an abrasive into any blasting apparatus. Further information can be found on the Health & Safety Authority website and also the Health & Safety Executive website in the UK. Chronic Obstructive Pulmonary Disease (COPD), also known as Chronic Obstructive Airways Disease (COAD), is a blanket term for obstructive lung conditions like bronchitis and emphysema. These conditions reduce the airflow out of the lungs. The Health Service Executive in the UK estimates that 15-20% of all COPDs could be work related.

These shocking figures could be prevented by taking the proper precautions, including wearing the correct Respiratory Protective Equipment. Here are some of these chronic conditions: Asthma - an obstructive lung disease linked to exposure to irritants or allergens (sensitisers) at work. A reversible shortness of breath. Extrinsic Allergic Alveolitis (EAA) - an allergic condition which affects workers exposed to biological dusts causing conditions including Farmers' Lung and Pigeon Fanciers' Lung. Fibrosing Alveolitis - also known as pulmonary fibrosis, can be caused by some occupational dust exposures, such as working with cobalt or hard metals in cutting tools. Related conditions, such as flock workers' lung and popcorn lung have been discovered recently. Pneumoconiosis - a group of restrictive lung diseases like asbestosis, silicosis and talcosis, where dust exposure causes debilitating lung scarring, Cancers - tumours, particularly of the nose and lungs, are related to substances commonly encountered at work, including asbestos, silica, chrome VI, nickel, cadmium and wood dust. These account for thousands of work related deaths each year, Heart Disease - dust affected lungs put extra strain on the heart, which can lead to rightsided heart failing. Some occupational exposures, like hard metal dust, can cause potentially fatal conditions such as cardiomyopathy. Very fine dust particles can cause inflammation of the heart and a higher risk of heart attack. Other Problems - exposure levels half the allowable for most workplace dusts overwhelm the body's first line of defense, the mucociliary clearance, that filters out dust in the upper respiratory tract, This can leave the worker more vulnerable to infections and more susceptible to occupational lung diseases. We are very excited to announce that Envirotrade are now distributors in Ireland for the Stealth range of personal safety respirators and filters. The unique design of these half mask respirators accompanied with the exclusive HEPAC (High Efficiency Particulate Air Composite) media pleated filters are set to shake up the RPE market. There are currently two types of filters available for the masks:

Each mask comes fitted with a set of filters (P3 (R) or PR (R) N) The respirators are available in two sizes - S/M or M/L The Stealth P3 (R) Personal Safety Respirator is a reusable half mask which provides complete respiratory protection against solid dust particles, metal fumes and liquid mists. With the respirator designed to meet the requirements of EN140 and the replacement filters to EN143, the Stealth P3 (R) Personal Safety Respirator provides and Assigned Protection Factor (APF) of 20. The Stealth P3 (R) Personal Safety Respirator offers comfort, ease of adjustment, high performance and a refined unobtrusive design. Using the exclusive HEPAC (High Efficiency Particulate Air Composite) Media within the construction of the pleated P3R filters, the favourable characteristics of both synthetic and glass filtration medias are combined to provide bacterial and viral filtration performance at low pressures. Typical applications include:

Some of the features and benefits are:

The Stealth range of respiratory protection can be purchased directly from our online store or by contacting Neal on 083 1066404 or [email protected]

We recently employed the services of Dan Devlin over at Vanguard Design to create a graphic that showed our product range. In the brief, we requested that it should be informative but simple and jargon free. We think Dan got it spot on and we are delighted with his work.

Anyway, enough of a plug for Dan. Here is what our product range includes: Head Protection Respiratory Protection Jackets & Torso Protection Gloves & Hand Protection Trousers & Leg Protection Foot Protection Our product range is growing daily and not all products are on our website. If you would like more information about any of our products or would like to see a sample please contact us through any of the following: Contact Page [email protected] 083-1066404 We understand how important your brand is to you. If you are like us, you have spent years promoting your brand to develop a stronger image in your marketplace.

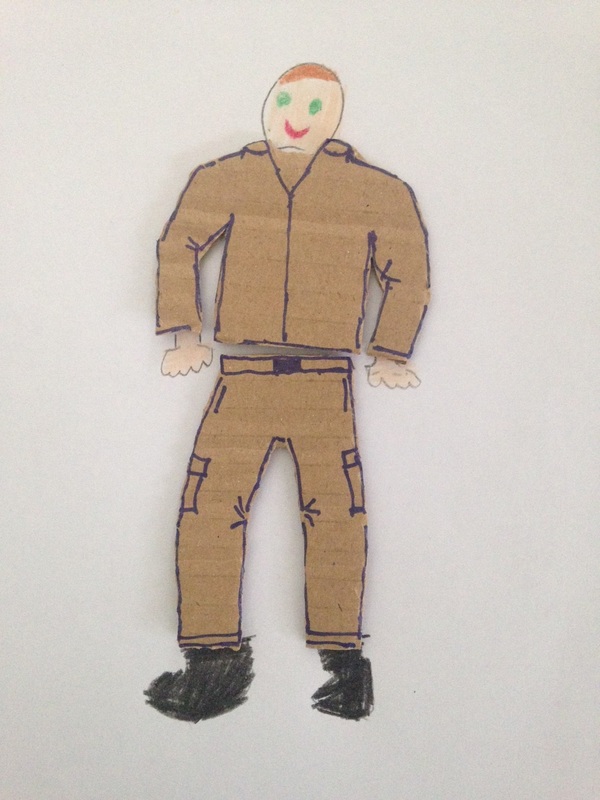

What better way to promote your brand than to proudly wear it on your chest? We can now offer a professional embroidery service to put your logo on workwear. We have stylish soft shell jackets, hi-vis clothing, hard wearing polo shirts and sweatshirts. We do not have a minimum order quantity. There is a €30.00 setup cost to have your logo digitised. All we need is a jpeg of your logo. If you would like more information or a quotation email [email protected] or call Neal on 083-1066404. Are you tired of wearing cardboard workwear?

If you need the performance but don't want to compromise on comfort you should try out our new range of Trojan Workwear. We stock a full range of workwear from boots and trousers to polos and jackets. Our workwear is tough and comfortable, and won't make you feel like the Michelin Man! Our tradesman trousers have more pockets than a snooker table and are as tough as old boots! The Trojan Trail Soft Shell Jacket will keep you warm and allows you to move freely. If you want to be super hot put a hoodie under your soft shell jacket. Our Action Lined Trousers will keep you as snug as a bug in a rug on the cold winter mornings! So, ditch the traditional poker stiff trousers and jackets and try our Trojan Workwear. We are excited to announce that we are now selling premium wood pellets. We have launched a brand new website just for our wood pellets - www.buywoodpellets.ie

Our wood pellets have been produced using 100% coniferous wood with no additives. The wood is sourced from sustainable forests in Latvia. Some of the advantages of using our pellets are:

They are available in 1000kg bags or 15kg bags, and can be ordered directly from the website for delivery throughout Ireland. #foracosyhome We all know the importance of having (and using) the correct Personal Protective Equipment, but do you know how often the item of PPE should be replaced or it's life expectancy? There is no legislation or Code of Practice stating the life expectancy of any PPE. it is recommended you follow the manufacturer’s instructions. The manufacturer must give the obsolescence deadline or period of obsolescence of PPE or its components. The date of obsolescence is the date from which the PPE becomes useless for its intended use or is no longer fit for its purpose. (Requirement under Annex II Article 1.4e, of EU PPE Directive 89/686, transposed in Ireland as European Communities (Personal Protective Equipment) Regulations 1993). Now that more trades are back to work, due to an upturn in the construction sector, it is time to check your hard hat (which was in the back of the shed gathering dust).

(b) not be stored in direct sunlight or in excessively hot, humid conditions because long-term exposure can weaken the shell; (c) be checked regularly for signs of damage or deterioration; (d) have defective parts replaced (if the model allows this). Parts from one model cannot normally be interchanged with those from another; (e) have the sweatband cleaned regularly or replaced.

If you need advise on any items of PPE, please contact us and we will be happy to help. PPE is easy to replace - your life isn't! As the country seems to be getting back to work, cranes are a familiar site on our city skylines once again. New build and renovation works are on the increase, and with that comes the risks of working at heights. Examples of work activities that are classified as working at height:

The following guidelines should be adhered to when carrying out work at height:

We have added a 'Working a Height' category to our store, with some of the main items of PPE used - harnesses, lanyards, etc. We can source any other items that you may require, so if it is not listed please get in touch and we will provide you with a quote. The HSA have produced a set of guide lines on the 2007 regulations which you can download below. |

Neal ChristopherNeal is the MD and founder of Asbestos Safe. He has 20 years experience working with Asbestos and hazardous waste and decided to bring that experience to the safety industry. Archives

October 2019

Categories |

RSS Feed

RSS Feed